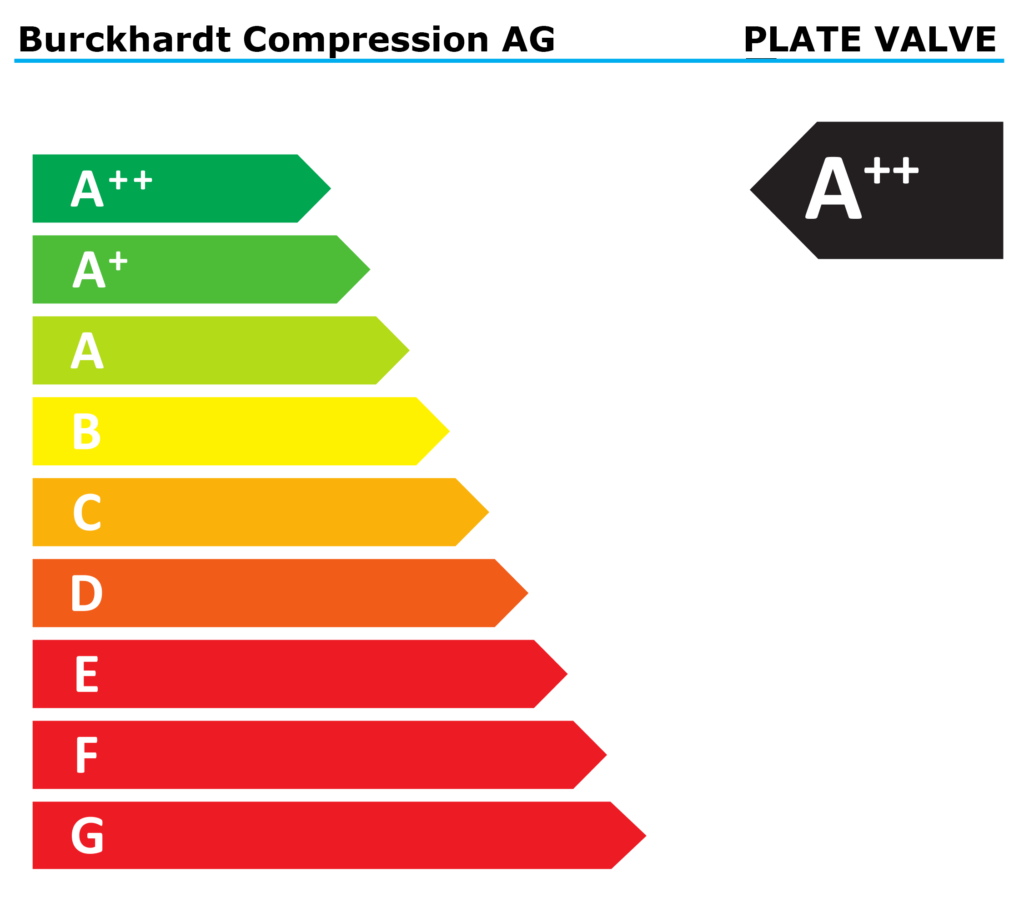

0.61 kg CO² eq / kg valve

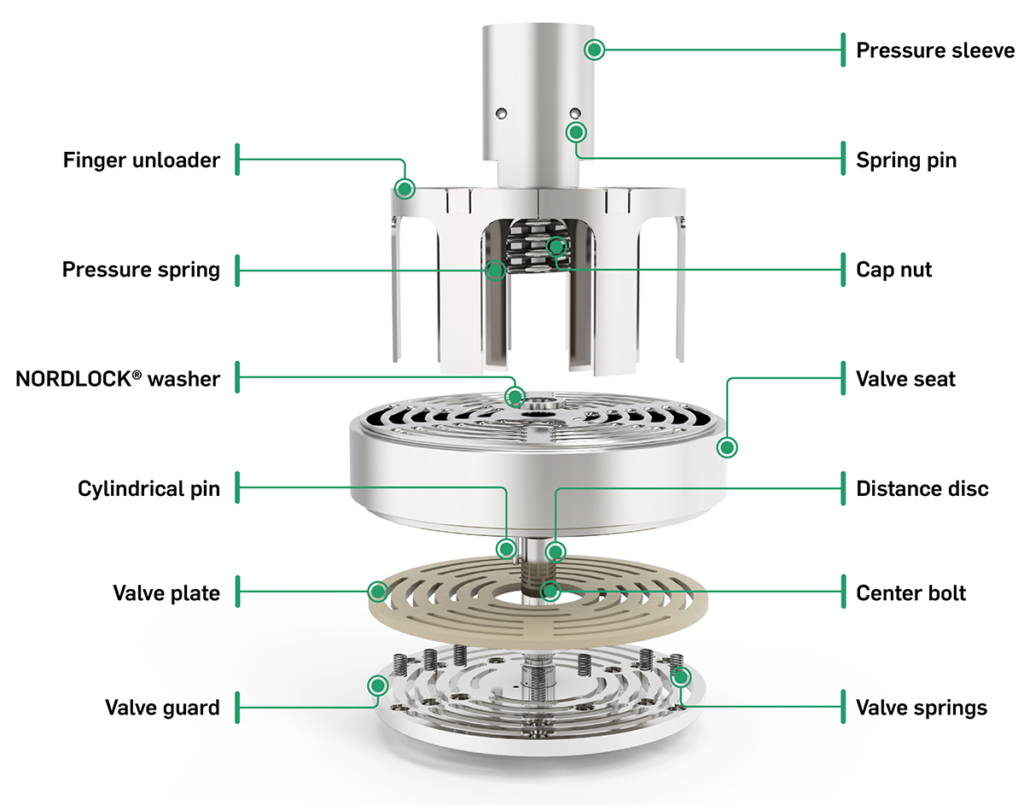

CnHm, H2, Air, N2, CO2, SO2, CO, NO, NO2, N2O

Burckhardt Compression AG

Franz-Burckhardt-Strasse 5,

P.O. Box 3352

CH-8404 Winterthur

Switzerland

Stay up to date with our newsletter